Wilson Transformer Company have extensive experience in designing power and distribution transformers according to Australian and/or International Standards including but not limited to AS2374, IEC60076, ANSI C57 and BS171.

All power transformers use circular, stacked step-lap cores. A range of winding types are used including layer for smaller power transformers, helix, multi-start helix tapping windings to reduce short circuit forces, and disc windings for larger power transformers.

Distribution transformers use proven non-circular wound or stacked step-lap cores to optimise performance and cost. For other than small distribution transformers and transformers with higher secondary voltages, the low voltage windings use sheet conductor to achieve high axial short circuit strength. The high voltage winding are of multi-layer construction. Epoxy diamond dot insulation is used throughout the windings, which when cured, contributes to achieving high short strength products.

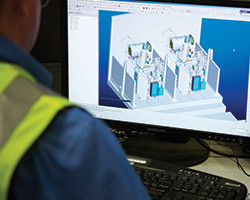

In order to optimise the electrical and mechanical design of our products, we use software ranging from tender optimisation programs and detailed in house developed programs to sophisticated finite element modelling (FEM) including VIT, ANSYS (Mechanical CFD electromagnetic), PTC CREO ProE and Solidworks for mechanical 3D solid modelling.

The programs utilise customer loss evaluation formulas to optimise the design and calculate impedance and losses; dielectric strength during impulse, induced and partial discharge tests and service conditions; short circuit withstand strength; cooling performance including winding hot spot temperatures and sound levels.

Our mechanical design is completed using 3D solid modelling, FEM structural/thermal analysis of critical components and other linked programs. Design aspects that are addressed include clearances for test voltages, mechanical strength for lifting, short circuit strength, transport and earthquake conditions, vacuum and pressure withstand, transport and site mass, dimension constraints and customer fitting requirements.

For power transformers, secondary control wiring is designed using E3 software to create the control schematics, terminal plans, BOM, label lists & wire lists, as well completing the design of control panels, including layouts and wiring.

Design reviews with our engineering team can be performed at either our manufacturing facilities or our customer's offices.

Products Overview

Products Overview

Power Transformers (≤550MVA)

Power Transformers (≤550MVA)

Distribution Transformers (≤5,000kVA)

Distribution Transformers (≤5,000kVA)

Compact MV Substations

Compact MV Substations

Special Applications

Special Applications

Monitoring & Control Solutions

Monitoring & Control Solutions

Service And Support Overview

Service And Support Overview

Site Installation and Testing

Site Installation and Testing

Transformer Assessment

Transformer Assessment

Upgrade, Repair and Refurbishment

Upgrade, Repair and Refurbishment

Storage & Consignment

Storage & Consignment

Spare Parts

Spare Parts

Oil Sampling, Analysis & Diagnostics

Oil Sampling, Analysis & Diagnostics

World Class Capabilities Overview

World Class Capabilities Overview

Design

Design

Services and Support

Services and Support

Standards & Compliance

Standards & Compliance

Supply Chain Management

Supply Chain Management

Generation

Generation

Transmission

Transmission

Distribution

Distribution

Infrastructure

Infrastructure

Industrial

Industrial

Oil & Gas

Oil & Gas

Mining

Mining